Standard Custom Designs including Quick-Open ASME available Engineer Support. 216800 14000 1710000 100 300.

Shell Thickness Calculation Under External Pressure In Pressure Vessels Youtube

1 He 0785varG2Pe end load external pressure 07851212520 0.

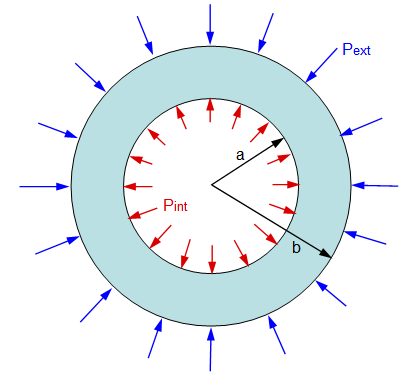

. In practice this is not so predictable. 4 HDe pi4 B2 Pe end load external pressure PI4 113762 0 0. MinPint1Pint2 maximum allowed design pressure This sheet cannot be used to check for allowable exterior pressure loads.

At Large end OD. PRESSURE VESSEL SHELLS MATERIALS FUEL CELL CARS A fuel cell. Crown radius of torispherical heads in.

The results of the vessel calculation consist of a Tabular report Vessel Drawings Bill of Materials and the Audit Reports Book. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors. If a 500 inch diameter vessel is 90 filled with a fluid of density 00362lbin³ and an over-pressure of 30psi is applied at the surface of the liquid the maximum pressure at the top of the vessel will be 30psi whilst the maximum pressure at its base will be 4629psi.

External Design Pressure Diameter of ShellHead Design Temperature Allowable Stress of Shell Joint Efficiency Corrosion Allowance Formula used Result t. 1 pressure vessel. 14Test Press P 13 MR 30 13 1mTp 39.

This template in excel provides blank data sheets for agitators and vessels. Trunnion lifting lug design. Rajeev383 when you calculate a cylinder to external pressure per ASME VIII there is no such thing as an allowable.

Psi mm F psi mm. 5 HT H - HD face load 23191 - 20425 2766. Design of dish under internal pressure.

Design of dish under external pressure. Tangential edge support Stress and Deflection Equation and Calculator. Calculation of Bursting Pressure.

Download File - Lifting Lug Design Spreadsheet. Any smooth figure of revolution if R 2 is less than infinity Uniform internal or external pressure q forceunit area. Design of Curved ends thickness.

Actually I have to design a long horizontal pressure vessel18000mm where thickness due to internal pressure is coming out to be 7 mm but in case of external pressure it is coming out to be 17 mm for which I need stiffeners. 90000. These characteristics are not important for.

External pressure can be caused in pressure vessels by a variety of conditions and circumstances. Presentations - DeWatering with ESP Presentations - Rod Pumping Gas Wells. All software provided As-Is with no warranty expressed or.

Assume a thichess if one is not already determined. - Vessel Supports Spreadsheet As per Pressure Vessel Design Manual-Dennis Moss. The design pressure may be less than atmospheric due to condensing gas or steam.

Design pressure p - 30 Nmm2 300 bar Design Temperature T. Program calculates trunnion type lifting lug commonly used to attache spreader bar slings on pressure vessel. Calculation of Hydrostatic Test Pressure.

UG-27c12 This sheet will not calculate thick walled vessels Treq 05Do2 Use the Weld Efficiency program to calculate El and Ec. Treq in Treq. Containing 3 sheets this tool has 3 detailed tables for you to fill in including some notes to help.

SHELL DESIGN THICKNESS CALCULATION BOTTOM PLATE ANNULAR BOTTOM PLATE DESIGN INTERMEDIATE WIND GIRDER DESIGN WIND DESIGN ANCHOR BOLT CALCULATION. P design internal pressure psi P a allowable external pressure psi P s design external pressure psi R s outside radius of spheres and hemispheres t thickness of cylinder head or conical section in. PD 2 SE 06 P PD 2 SE 06 P 195691.

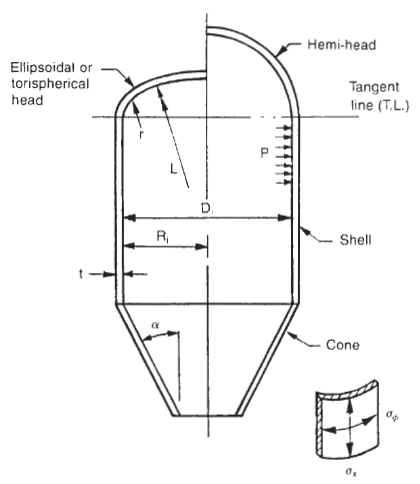

Design of cylindrical shell under external pressure. How to calculate I-BEAM. T o equivalent thickness of cone in.

2 HP 2varb314varGmP contact load 20135314121250201 0. From calculation development in. Roarks Formulas for Stress and Strain for membrane stresses and deformations in thin-walled pressure vessels.

With many decades of accumulated pressure vessel engineering and design experience the IMAGE team can help you avoid the common pitfalls and provide a repeatable path to success. At Large end ID. Before doing anything with this tool it is recommended that you Save as first.

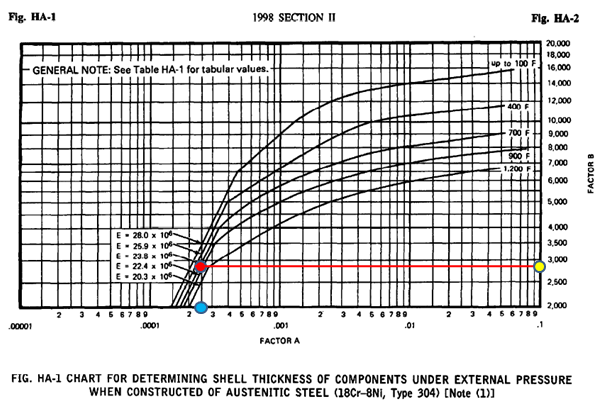

Free Applications Scripts for Petroleum Oil Gas activities. To withstand external pressure two metal characteristics are important Youngs Modulus E Yield strength S. 12 13Hydro Test UG-99bpressure measured at top of vessel rounded up.

P D Temp S E CA. For well over 10 years one particular area of strength has been ASME Section VIII pressure vessel engineering and design. END OF THIS WORKSHEET GMs Fuel Cell Car BASIC STEAM ENGINE BOILER Shell Longitudinal stress S L Shell Circumferential stress S C Spherical head stress S H PR 2 t Design shell thickness ts MATH TOOLS LINKS Actual Thin Wall Pressure Vessel Stress SPREAD SHEET METHODS.

4629 90 x 500 x 00362 30. Design of Pressure Vessel Design of Cone under Internal External Pressure Material Design Internal Pressure Design External Pressure Design Temperature AllStress at Design Temp. Often vessels are design for some amount of external pressure to allow for steam cleaning and the effects of the condensing steam.

The design of solid pressure vessel comprises. Pressure Vessel Calculations-ASME Section VIII Division I Basınçlı Kap Tasarım Hesaplamaları Ahmet Oven. Full PDF Package Download Full PDF Package.

X and ISO 3183. Design of cone under internal and external pressure. 3 HD pi4 B2 P end load PI4 113762 201 20425.

Joint Efficiency Radiography Corrosion Allowance Polishing Allowance Thinning Allowance Type of Cone Provided Thickness OD. Up to 24 cash back Tools for Design Estimation of Pressure Vessels and Shell Tube Heat Exchanger. Design of shell under internal pressure.

Bill of Materials All components belonging to the vessel under design are. Design of vessel thickness. Calculations per ASME code include.

Thickness Calculation Of Pressure Vessel Shell - Free download as Excel Spreadsheet xls PDF File pdf Text File txt or read online for free. MDT XPT Pressure Plotting SoftwareSpreadsheet. Other vessels are in vacuum service by.

Nasrul M Asral namasral Submitted On. FORMED HEADS AND SECTIONS PR P No Equipment Internal design pressure 1 2 3 FORMED HEADS AND SECTIONS PRESSURE ON CONCAVE SIDE E t S t D Shell Maxallowable Joint. ASCII Report All relevant data of the vessel are printed out including the results of numerical calculation and geometrical dimensioning.

10 ASME Sec II part D Fig G From Fig G using LDo and Dot From Fig HA-3 for 304L ASME Sec VIII Div 1 Maximum Allowable external working UG-28 Pressure A B Pa 4B3. This sheets are labelled. ALLOWABLE STRESS REFERENCE Calculation Reference API 650 Oil Tank Design Pressure Vessel Design Calculation Preview.

Volume of the pressure vessel.

Hand Calculations Pressure Vessel Engineering

Pressure Vessel External Pressure Calculations

External Pressure Design Thickness Calculation For Pipe With An Example The Piping Talk

Xls Asme Pressure Vessel Design A Antonio Gamino Academia Edu

External Pressure Pressure Vessel Engineering

External Pressure Pressure Vessel Engineering

External Pressure Design Thickness Calculation For Pipe With An Example The Piping Talk

0 comments

Post a Comment